Hello, and welcome to this week’s ‘Back to Earth’ podcast with me, Chris Brookman.

This week I’m going to cover a presentation that I did to the Green Register and the ASBP in Bristol, which is basically a wood fibre 101 which really goes into detail about wood fibre, the way it’s manufactured and all the different uses of it.

What exactly is wood fibre?

Wood fibres are made from tiny cellulose microfibres, so these are short sections of cellulose in a long chain and they’re held together with a lignin resin which is a natural resin that is part of the tree. They create structures which are almost like long drinking straws – very, very small obviously – and these are called xylem. These essentially in the tree are for transporting moisture from the roots all the way up to the branches at the top and out to the leaves. They can transport huge amounts of water a very, very long way vertically, which means they’re incredibly good at transporting moisture.

Now, on water you get a really high surface tension and that combined with the hydrophilic nature of the wood fibres, creates a way of transporting huge amounts of moisture very, very quickly. But also because they’ve got a huge surface area, the wood fibres, you can also adsorb a vast quantity of moisture vapour onto the surface of them.

Wood fibres also have unusual phase change properties. So when water is adsorbed onto the surface of them you get a certain amount of heat released and it creates some really unusual properties, which mean that wood fibres behave significantly differently to synthetic fibres, for example.

Wood fibre also has a very high specific heat capacity, which means its ability to store heat for a given quantity or a given mass. That’s actually increased as it adsorbs water as well, including a small amount of moisture in the process actually boosts the thermal mass of the fibres. This and the fibres’ ability to manage moisture makes it incredibly useful for retrofit because they are very good at keeping existing timbers dry.

So natural fibre structures, the plant fibres, are incredibly complex – much more complex than synthetic products that we create and that gives them really, really useful properties over a wide range of areas, which is why they’re so useful in insulation and building products.

So how is wood fibre insulation made?

There are essentially three different types of wood fibre. There’s a wet processed rigid board. There’s a dry processed rigid board and there’s the flexible wood fibre which is a thermally bonded non-woven product.

The wet and dry process, as I said, are used for making all sorts of rigid boards of all sorts of densities and the non-woven process is used for all sorts of different flexible wood fibre products of all sorts of different densities, again depending on what the application is.

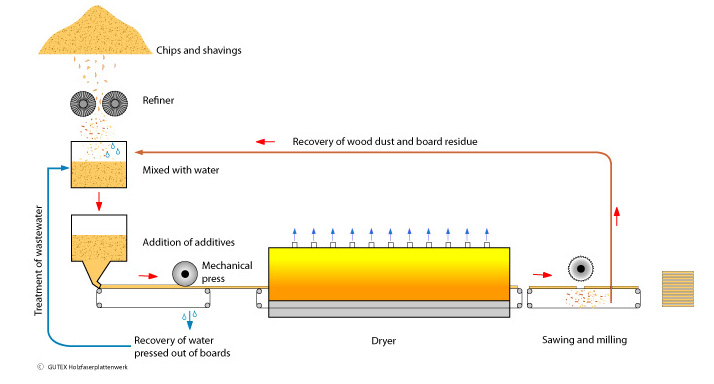

Now for the wet processed boards, essentially you take wood shavings, wood chips, all sorts of offcuts, all sorts of waste wood effectively. It goes through something called a refiner which grinds the wood up into very small pieces. This is mixed with water and essentially boiled up and that releases a lot of the water-soluble compounds in the wood which are then removed, and then they add certain additives depending on what the properties they’re looking for are. This goes onto essentially a big straining bed and the moisture is sucked out of it and pressed out of it, and then that goes through a dryer and a steamer and all the wood fibres are steamed and essentially bond to each other loosely. That forms 20ml boards which are then laminated up to different thicknesses.

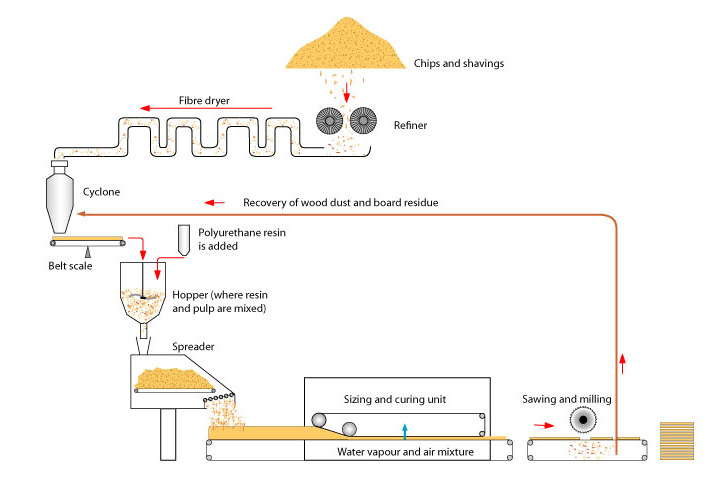

The dry processed boards go through a similar process to begin with, in that the waste timber is refined, but then that is actually dried. It goes through a big dryer and then gets mixed with a polyurethane resin which is then spread out onto a conveyor, graded to an even thickness and then squashed down to its final thickness and then cured in an oven again with steam and machined up to the final size that you need.

Now those boards are produced as a homogenous board and they can be produced to any thickness pretty much, but they are a single layer all the way through, whereas the wet processed boards are always a multiple of normally 20ml.

Finally, the flexible wood fibre products – so the thermally bonded products. Essentially the wood again goes through a refiner and is ground up into coarser fibres that go into the wood fibre board. That’s blown with a polyester fibre into a slab. That material is heated and gently pressed and the polyester fibres soften and glue the whole structure together. You can produce anything from 40ml up to 240ml thickness, so you can produce some quite thick material with that.

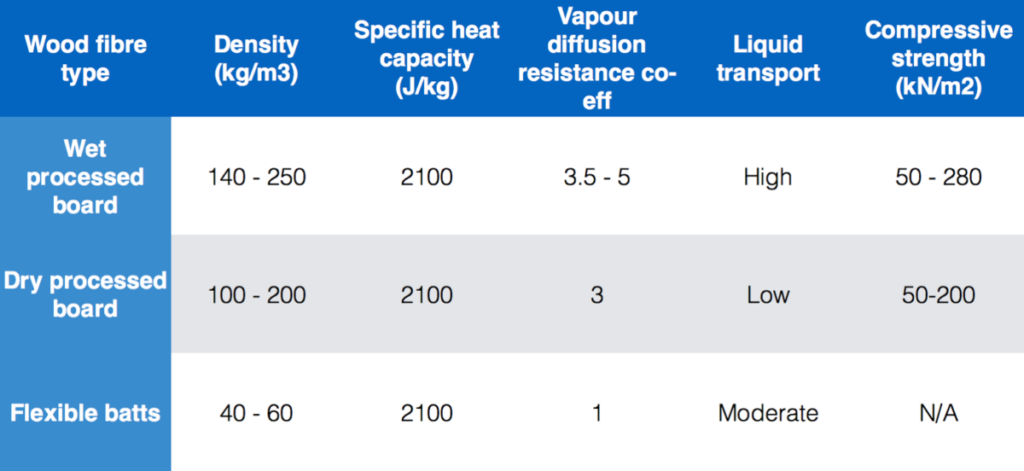

All three different processes do produce quite different products and they all have some unusual and very, very differing properties. Looking at the wet processed boards, they tend to range from 140 up to 250 kilos per m3 in density. The dry processed tend to be slightly lighter, between 100 and 200, partly because to achieve the same mechanical strength you don’t need quite as much material because the polyurethane glue is doing the job. And then the flexible bats tend to range between about 40 and 60 kilos per m3.

Now the specific heat capacity is roughly the same for all the boards because they’re nearly all timber, but because the density varies then obviously the amount of heat storage each product can have, obviously is quite different. Looking at the wet processed boards, the vapour diffusion coefficient form is between 3.5 and 5. The dry processed boards are actually slightly more vapour permeable because they tend to have a slightly more open structure and be slightly less dense. They have a diffusion resistance coefficient of around 3 and the flexible bats tend to be about 1, so they obviously are very vapour open.

However, the main difference really between all the products is the liquid transport capability. So wet processed boards, they’re quite dense. The fibres are as they are in the tree and they are extremely capable of moving moisture. So if you do get moisture into your insulation, those boards will quickly soak it up and transport it through the structure and allow it to evaporate out.

The dry processed boards, whilst they are very vapour permeable, are not able to transport moisture very quickly, simply because the polyurethane resin coats the individual fibres and prevents transfer of moisture from one fibre to the next.

The flexible bats are kind of in between the two really. They’re quite a loose material in terms of the fibres aren’t very close together, so they’re not quite as good at transporting moisture.

Then finally the compressive strength of all the boards tends to be engineered depending on what the final use is. Simple squarage insulation tends to be about 50 Kilopascals and when you’re going up to roofing, sarking boards, then they can go up to anything around 200 to 280 Kilopascals, which is pretty strong.

In terms of use, the wet and dry processed boards are used for roof insulation externally and internally, for wall insulation and floor insulation. So anywhere that you can use obviously a solid, rigid board. Dry processed boards are generally not used for internal wall insulation though, because of their inability to transport liquid moisture.

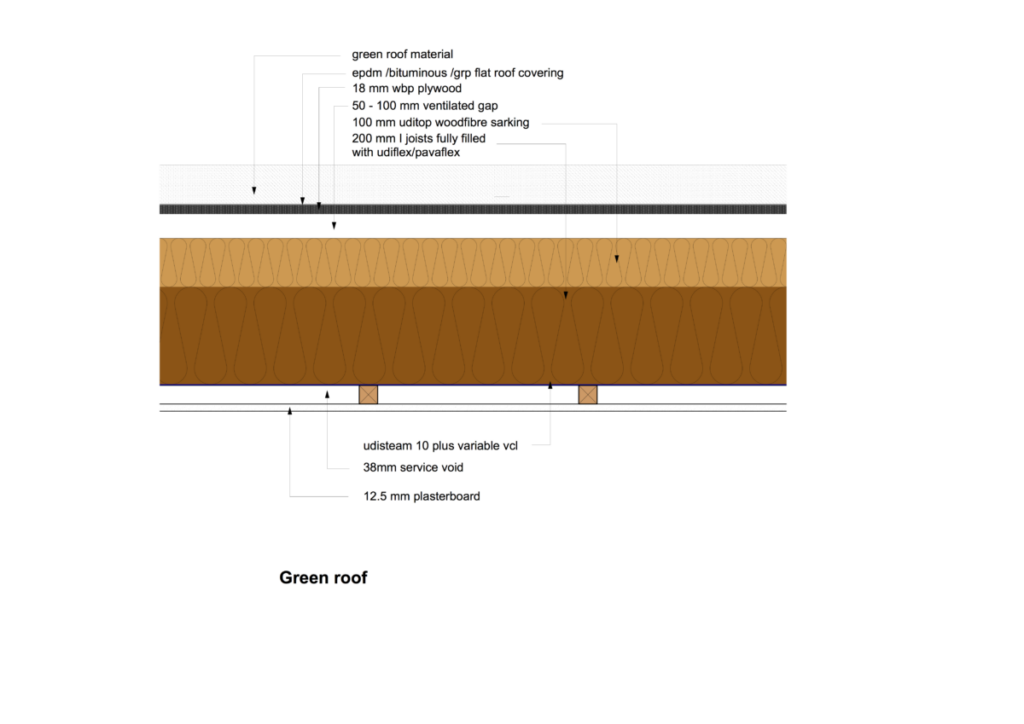

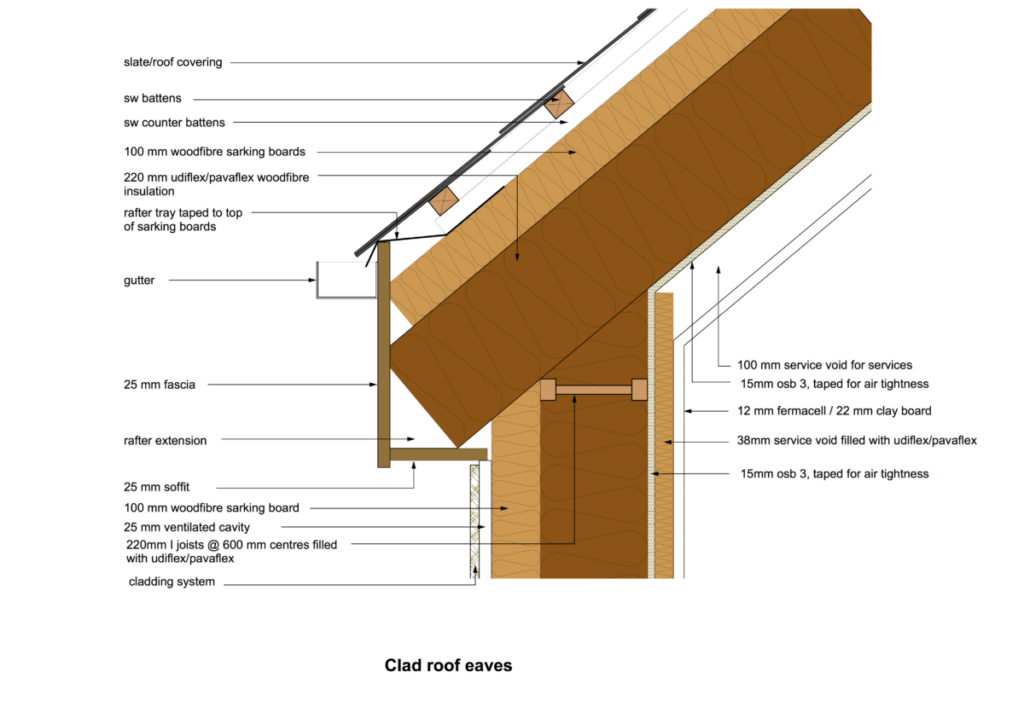

The flexible wood fibre that is produced is nearly always used as an insulation between timbers. This is quite a solid material, so you tend to get a very good friction fit and it doesn’t slump at all. So with those different products you can do all sorts of different construction. You can do flat roof construction, both vented and unvented. Externally you can have rendered facades or clad facades. Again, you can use it on the roof with tiles or zinc or green roofs, and then typically down to plinth level you would take your wood fibre down to DPC or thereabouts. Anything below DPC and ideally anything less than 300ml above ground level, you would switch over to polystyrene or extruded polystyrene, so that you don’t get any issues with moisturing.

Wood fibre boards and wood fibre products generally allow you to build extremely simple timber frames. That’s really one area that the product works exceptionally well. Typically you would have a timber frame depth upwards of 140ml, depending on your target U value. The rigid boards would then go on the outside of that timber frame. Now the way that you detail the boards around your openings as a standard detail, gives you incredibly low C values. So typical accredited construction details would give you C values of 0.15 watts per metre per Kelvin, whereas with wood fibre you’re looking at 0.3. So you’re looking at an 80 per cent reduction in heat loss around your openings in your timber frame. That allows you actually to target much higher U values than you would with for example a PIR board in between the frame, simply because you’ve got significantly less heat loss around the openings.

The other property of the wood fibre that really makes it excel is the high density. Now, if you use those high-density boards externally, they obviously keep you warm in the winter- which is the easy bit, but they also store a huge amount of heat in the summer. So during the summer they will, depending on the thickness, store most of the day’s heat from the sun and they actually prevent that from entering the building. Then as the external environment cools, the heat then gets radiated back outwards again. So using wood fibre you can turn what is essentially an extremely lightweight structure, a timber frame, into something that behaves much more like a masonry structure, something that’s very, very thermally massive, so you create a very stable internal environment.

Now the wood fibre insulation can be used on the outside of masonry as well, just as well as in timber frame, but I’m going to look at internal wall insulation because it’s a bit more interesting than the external.

Typically if you were using rigid boards, you would flatten the wall first with a render layer and then apply the wood fibre insulation and then you render over the top of it. Or if you’re using the UdiRECO system, you would fix that straight back to the wall. The board will accommodate the unevenness and then again you render onto that board.

Now essentially what happens during the winter months normally, is that moisture in the air inside the building migrates slowly through the wall or through the insulation and meets your masonry. Essentially it begins to condense at the interface between the insulation and the wall. To prevent too much moisture accumulating there, most systems include some sort of vapour control air, so with the UdiRECO and the UdiIIN system there’s a vapour controlling plaster and with the Permatex systems there’s a latex layer within the board that’s slowing the flow of moisture into the wall. Essentially you get an accumulation of moisture at the interface between the wood fibre board and the wall, but because of the huge storage capacity of the wood fibres that is then stored during the winter months without any detriment to the thermal insulation properties of the wood fibre or in terms of its structure. In other words, it’s not going to rot.

As the weather then begins to warm up in the spring, you begin to get more moisture movement. The sun shines against the wall and that will actually dry some of the moisture back towards the interior, but then as you get warmer winds that also begins to draw moisture out of the walls, so the walls dry back out again. By the middle of the summer the walls are essentially bone dry again.

If you calculate the U value that you would expect for a wall just using standard conductivity of wood fibre, you would get a particular U value. But what tends to happen with internal wall insulation only, and only on the inside of masonry, is that you get an increase of performance anything between 20 and 50 per cent, depending on the thickness of the board. Actually the improvement is more significant the thinner the board, so I’m guessing it’s an effect that occurs at the interface between the board and the wall.

Now we’ve got several long term studies that indicate savings well in excess of savings that you would expect by simply reducing the U value, simply because the walls are performing that much better. We’ve also measured walls with our own U value testing kit. We started with a brick wall that had a U value of 4.25 when we measured it, which actually was worse than we calculated. With our 23ml UdiIN 2cm board we were expecting it to achieve a U value of 2.1, but when it was measured the U value was 1.4. So it was performing about 30 per cent better than we actually expected. The 23ml board actually reduced the heat loss through the wall by about two thirds. Now that is a huge saving for such a thin board and it’s all down to the special effect that you get with the interaction between moisture and wood fibre when it’s in an internal situation.

This isn’t a detrimental process, the boards last a very, very long time in multiple decades. It’s not a process of absorbing water and the boards getting wet and slowly decaying. So this is something that happens year on year, but when I finally find out exactly what the process is, I’ll let you know.

Finally then, why is wood fibre so useful?

PIR and very high performance insulation can create very, very thin structural elements, but it’s literally only on thicknesses is the wood fibre outperformed by things like PIR. On every other metric, so acoustics, diffusivity, moisture management and things like achieving as design performance, on site risk from rain and moisture, fire risk even and also environmentally, every single one of those other metrics, would fibre outperforms essentially everything else, or every other synthetic material.

For a given U value, wood fibre has almost twice the decrement layer of mineral wool and at least 65 per cent more than PIR. So essentially if you have two walls that have the same U value, it will take twice as long for the heat to get a wood fibre wall as it will through a wall using mineral wool. How that translates to a building is that during the summer you end up with a building that essentially doesn’t overheat. It maintains its internal temperature and stays very stable internally.

In volume for volume, flexible wood fibre stores about 12 times more heat than fibreglass and rigid wood fibre boards store about 12 times more heat than PIR, and around 15 times more heat than EPS. So again, on every metric the wood fibre is outperforming the synthetic materials. This creates buildings that are very stable in the summer. You’re reducing your overheating risk, so you’re making the building much safer for occupants. Also that heat absorption lowers heat demand. It can absorb heat during the day and slowly release it during the evening, so again it’s keeping the internal environment much more stable. It’s ability to manage moisture also preserves timber, so wood fibre is able to buffer humidity in walls and even out humidity so that you don’t get accumulations in existing timber. It prevents mould growth and it enables safe refurbishment of building.

Finally, whilst wood fibre naturally contains formaldehyde, something you can’t take out of it, it comes from the wood itself, it gives off very few VOCs. When you combine that with its ability to buffer moisture, it has a really beneficial effect on indoor air quality which again makes the internal environment very, very healthy for its occupants.

Hopefully that gives you some new insight into wood fibre insulation and what it can do. If you have any other questions about wood fibre insulation or other sustainable building materials, please feel free to email me at Chris@backtoearth or alternatively give me a ring on 01392 861763.